BACK TO RESEARCH WITH IMPACT: FNR HIGHLIGHTS

Polyurethanes (PUs) are widely used plastics, produced in large quantities each year, and found in products like foams, coatings, sporting goods and medical devices. However, their production relies on toxic chemicals, which can cause health issues and environmental harm, and most PU products are difficult to recycle. An eco-friendly alternative has been developed and is being fine-tuned by researchers.

Considered “commodity plastics”, 24.7 million tons of Polyurethanes (PUs) were produced across the world in 2021. The wide selection of compounds available for their synthesis makes them extremely versatile. As a result, they are, for example, used in foams, coatings, adhesives, automotive parts, as well as medical devices, and sporting goods. However, the chemicals used to produce them produce significant risks to human health.

“The synthesis of PUs requires the use of toxic isocyanates, which present respiratory and dermal hazards and can cause chronic illness or even death upon overexposure. Moreover, the majority of PU products are thermosets, which means they are almost non-recyclable, unlike some other commodity plastics, such as PET,” explain chemists Arpan Datta Sarma and Sergei Zubkevich, both Postdocs at the Luxembourg Institute of Science & Technology (LIST) at the time of writing.

Eco-friendly non-toxic alternative, but not without challenges

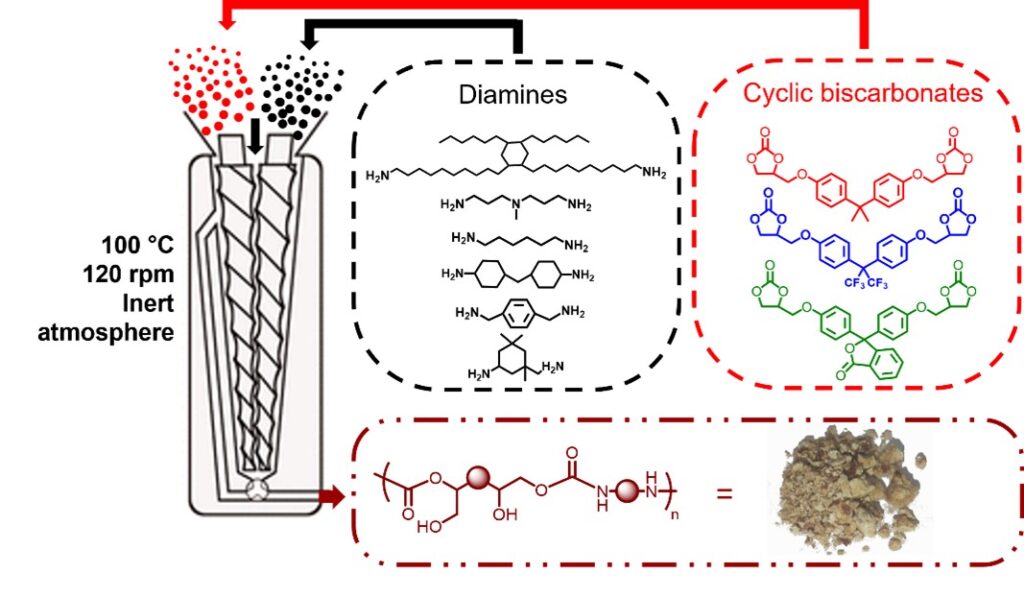

An eco-friendly class of alternative materials known as polyhydroxyurethanes (PHUs) can be made using non-toxic materials, including carbon dioxide and renewable feedstocks, whose use also helps to reduce their carbon footprint. However, there are real challenges that have limited the use of such materials to date.

“Many cyclic carbonates can be prepared using renewable bio-based sources, reducing the PU industry’s dependence on fossil resources. In the last decade, scientists have significantly improved synthetic approaches to the green synthesis of cyclic carbonates and corresponding PHU polymers.”

“But, in the field of PHUs, a few primary challenges exist: long reaction times (hours even days), which subsequently limit the molecular weight of thermoplastic PHUs, use of solvents in most cases, which is less than ideal, and the high moisture absorbance of resulting polymers, leading to a loss of mechanical properties at high humidity levels.”

Slow reactions and water absorption among issues

These problems are caused by the nature of the chemicals used, which react more slowly than isocyanates, and by the structure of the PHU polymer itself, which naturally absorbs water because it has many alcohol groups that attract moisture.

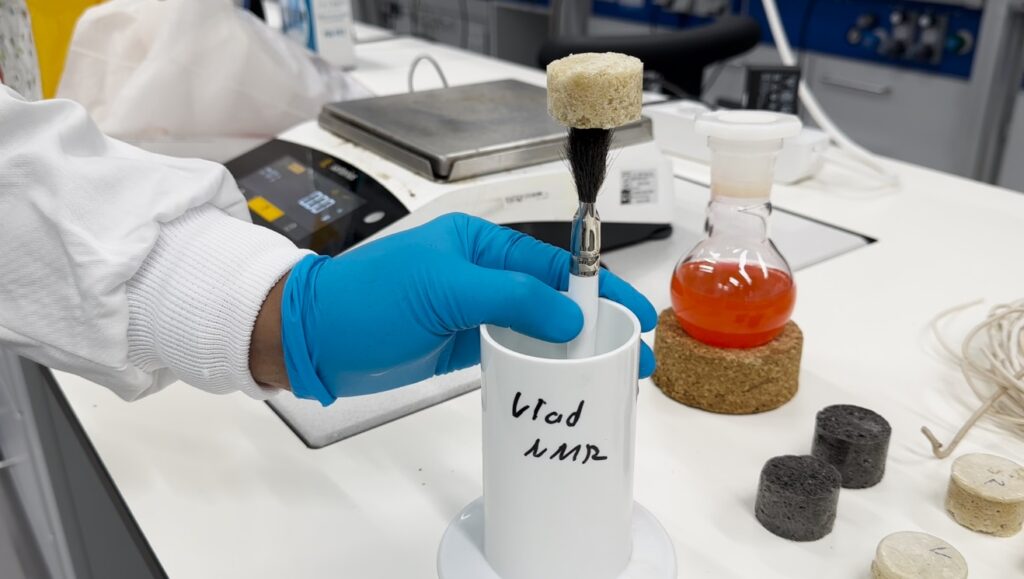

“We have addressed both issues by employing reactive extrusion to expedite the synthesis of the PHUs, followed by subsequent chemical modification to fine-tune the final polymer structure and properties. The results are highly promising; we successfully obtained PHUs with attractive mechanical performance and developed a method to reduce moisture uptake,” the duo explains.

Reinventing PHU synthesis

One of the recent discoveries made in the group changes the perception of chemistry involved in PHU synthesis. By tuning the structure of both cyclic carbonate and amine functional groups, the researchers were able to produce high-molecular weight PHUs within short periods of time and at moderate temperatures. In addition to significantly accelerating polymerization, this approach also drastically reduced unwanted side reactions, which previously hindered the achievement of high molecular weights PHUs and optimal mechanical properties.

“It was amazing to see, even with our preliminary experiments, how extremely fast this chemistry can be” – the duo tells us. “We were able to observe how the polymer was forming with the naked eye in a matter of minutes. This is what we have never been able to see before with cyclic carbonate chemistry. This discovery seems highly promising not only because the reaction is fast and we get high molecular polymers with excellent properties, but also because the functional groups required to utilize this approach are relatively easy to incorporate into a variety of precursors, with the potential for levels of versatility approaching that of conventional PUs. We look with hope to the future developments based on our discovery“.

Investigating environmentally friendly & efficient methods

Arpan Datta Sarma’s focus is on investigating efficient methods for synthesising polyhydroxyurethanes (PHUs) in an environmentally friendly manner, with the aim of utilising them as replacements for polyurethane (PU) foams in a range of applications.

“I am developing new effective methods for PHU synthesis using reactive extrusion. This approach allows us to conduct polymerization in the absence of the solvent thus reducing potential harm to the environment and the whole cost of the process. Moreover, this approach provides higher molecular weights of obtained PHUs and thus better mechanical performance. We have also introduced a new approach to foaming thermoplastic PHUs resulting in robust foams, similar to the ones produced using conventional PUs, however they can be easily recycled like any other non-cross-linked material,” Arpan explains.

Using chemical modification to enhance properties

Sergei Zubkevich is developing ways to enhance polyhydroxyurethanes (PHUs) by imparting them with new properties including moisture resistance, CO2 sorption capability, and fluorescence. Through chemical modification, he has worked on enhancing the properties of already obtained PHUs.

“By carefully designing the structures of PHU polymers, I have been able to employ simple and efficient modification approaches to reduce PHU moisture sensitivity and further impart them with unique properties. For example, we can now synthesize PHUs capable of CO2 sorption and storage. Additionally, we are developing new PHU-based materials for high-performance composites that can be used in automotive industry and wind energy.”