BACK TO RESEARCH WITH IMPACT: FNR HIGHLIGHTS

Plants synthesise a wide range of natural molecules, described as plant metabolites or phytochemicals with enormous industrial potential in anything from cosmetics to pharmaceuticals and biocontrol. To lessen the environmental impact of exploiting these phytochemicals and keep production viable, researchers are seeking ways to upscale, increase and optimise their production.

The demand for scientifically validated ingredients of global personal care and cosmetic markets is growing. As a result, companies and researchers are turning their attention to natural resources, such as phytochemicals. This has created a need to develop methods to upscale, increase, elicit and optimise the production and extraction of these molecules.

Concerns about climate change, sustainability and energy costs can have an impact on the way phytochemicals from plants may be exploited. Projected increases in temperatures, changes in precipitation, and even water shortage all contribute to decreased agricultural productivity and quality.

This creates a need for innovative processes and sustainable biotechnological alternatives to produce value-added compounds and ingredients for different market sectors ranging from cosmetics, nutraceuticals, biocontrol, and pharmaceuticals, where there is an increasing interest in naturally produced molecules rather than artificial ones.

Bioprocess engineering to the rescue

Extracting these molecules from plants is a challenge, both due to environmental factors and the need to keep it on a scale where production stays viable.

An alternative to counter these constraints: bioprocess engineering, using living cells to produce value-added products, which also opens up the possibility of improving manufacturing processes, in terms of sustainability, productivity and ingredient recovery.

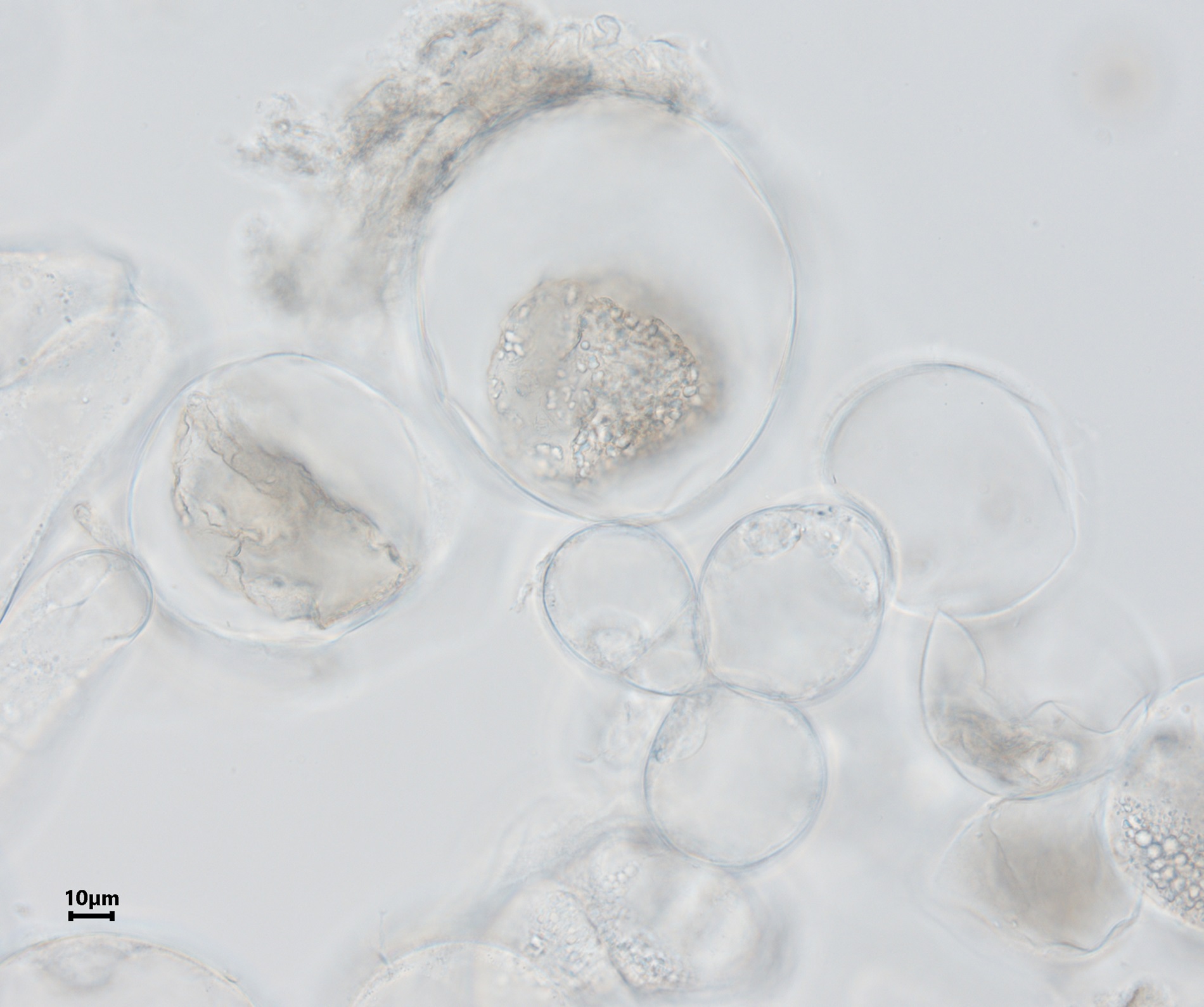

“Particularly, plant-cell suspension culture is a set of techniques designed for the growth and multiplication of cells using nutrient solutions in an aseptic, pesticide-free, and controlled environment.

“Therefore, research on this field turns out to be an interesting milestone to develop production and extraction techniques for different markets,” explains Diego Ríos Salgado, a bioprocess engineer working on the Biotechnologies and Environmental Analytics Platform (BEAP) at LIST.

“As society is moving towards a more sustainable approach to employ resources, our work on bioprocess engineering aims to guarantee a sterile environment to produce value-added molecules for large-scale commercial manufacture, either from plant cells or other microorganisms. ”Diego Ríos Salgado Bioprocess engineer working on the Biotechnologies and Environmental Analytics Platform (BEAP) at LIST

Plant-cell-cultures can be initially managed in small volume flasks.

A look under the microscope

Cell transfer to bioreactors

Cell recovery

Scale-up

Simultaneous use of bioreactors

The big 300-litres bioreactor

Finding the best ways for large-scale production

Diego explains this can be accomplished by identifying and establishing suitable methods for the large-scale production of specific cell lines containing innovative phytochemicals for different market sectors.

The presence of these molecules may be also enhanced by a set of techniques such as elicitation, which can stimulate the biosynthesis of specific compounds in living cells. Evidence also suggests that the efficiency of bioprocessing can be increased by the simplification of methods for product recovery and storing protocols to optimise a complete scheme.

“My colleagues and I successfully performed an upscaling process from hundreds of millilitres up to 300L of several innovative plant cell lines selected for their potential molecules of interest.rnOur role is to further develop these activities at higher scales to fit the market expectations such as in the FNR Jump21’s ‘ACCEDE’ project or the H2020 project “InnCoCells”.rn ”Diego Ríos Salgado Bioprocess engineer working on the Biotechnologies and Environmental Analytics Platform (BEAP) at LIST

Diego Ríos Salgado is a bioprocess engineer and lab technician in the Environmental Research and Innovation Department (ERIN) at the Luxembourg Institute of Science and Technology (LIST).

MORE ABOUT DIEGO RÍOS SALGADO

u003ch4u003eDescribing his work in one sentenceu003c/h4u003ernu003cemu003e“My efforts are focused on joining plant-cell suspension cultures and high-scale bioreactor processes to produce value-added ingredients for cosmetic markets.”u003c/emu003ernu003ch4u003eWhy he chose this pathu003c/h4u003ernu003cemu003e“Originally from Ecuador as an agricultural engineer, I have worked in the United States, and now in Europe where I obtained a phytopathology and bioprocess engineering degree.u003c/emu003ernrnu003cemu003e“Within the BEAP platform since 2021, I have developed diverse skills regarding bioreactor management, metabolite analysis and different software tools.u003c/emu003ernrnu003cemu003e“I have been attracted by the values, impact and novelty proposed by the research at LIST.”u003c/emu003ernu003ch4u003eWhat he loves about scienceu003c/h4u003ernu003cemu003e“Research is a discipline which never stops, and it is simultaneously the tool that helps society make deeper sense of the world around.u003c/emu003ernrnu003cemu003e“I think science lets us understand ourselves and the environment we1 are based on, where we come from, and we are headed. It provides us with answers if the right questions are asked.”u003c/emu003ernu003ch4u003eWhere he sees himself in 5 yearsu003c/h4u003ernu003cemu003e“Combining fields, as bioprocesses and biochemistry, allows us to explore innovative strategies in the interest of different sectors of industrial biotechnologies, within Luxembourg and Europe.u003c/emu003ernrnu003cemu003e“Personally, I enjoy my daily tasks at LIST, and I am always glad to develop new skills each day.u003c/emu003ernrnu003cemu003e“My current role at LIST allows me to be engaged in the technical expertise as well as in the research scheme. I enjoy my engineering career path and I see myself working within this specialityu003c/emu003e u003cemu003ein the long term”.u003c/emu003ernu003ch4u003eMentors with an impactu003c/h4u003ernu003cemu003e“I am thankful for my colleagues within BEAP. Dr. Jenny Renaut, Dr. Samuel Jourdan and Sébastien Planchon have endowed me with diverse skills to carry out a proficient job.u003c/emu003ernrnu003cemu003e“I am also grateful to work next to dedicated researchers as the ones from Dr. Jean-François Hausman’s team, especially Dr. Gea Guerriero, Dr. Sylvain Legay and Laurent Solinhac who have constantly provided me with innovative knowledge in Plant Molecular Farming.”u003c/emu003e

Related highlights

Spotlight on Young Researchers: Towards fair health for all

Access to essential health services is considered normal in high-income countries, while they are out of reach for many in…

Read more

Spotlight on Young Researchers: Improving protein folding prediction with statistics

Proteins are the building blocks of life: they play an important role in metabolism, immune defence and DNA replication. Their…

Read more

Spotlight on Young Researchers: Building AI tools to help fight disease

AI developments have led to improvements in disease research by enabling new approaches in the study of genes, molecules and…

Read more

Spotlight on Young Researchers – Revisited: From Luxembourg, to Cambridge, France, and an ERC grant

“Would matter be perfect, it would be boring” says Guillaume Nataf, who has an oozing passion for physics and teaching…

Read more

Spotlight on Young Researchers: Advancing ecosystem monitoring with remote sensing and innovative models

The health of terrestrial ecosystems is intricately linked to the sustainability and stability of society: forests, grasslands, and cropland, play…

Read more

Spotlight on Young Researchers: Unravelling the role of calcium signalling to overcome melanoma drug resistance

Cutaneous melanoma is the most serious type of skin cancer and the sixth most frequent cancer in Europe. Despite progress…

Read more