BACK TO RESEARCH WITH IMPACT: FNR HIGHLIGHTS

Over 50 years after the first Moon landing, interest is growing in returning. What was the case in the 1960s still rings true: Going to the Moon, with all the equipment needed, is beyond expensive. Using resources already on the Moon is considered the best way to limit the expense – researchers are working to make this possible.

“In-Situ Resource Utilization (ISRU) supports a future where we can survive and develop using resources already on the Moon, especially oxygen and metals contained in the dusty lunar soil. ISRU could drastically reduce launch costs and make long-term missions possible. In the long run, these technologies may help us live more sustainably in space, and even inspire cleaner, more efficient ways of producing materials here on Earth,” explains PhD candidate Francisco J. Guerrero-Gonzalez.

“In-Situ Resource Utilization (ISRU) supports a future where we can survive and develop using resources already on the Moon, especially oxygen and metals contained in the dusty lunar soil. ISRU could drastically reduce launch costs and make long-term missions possible. In the long run, these technologies may help us live more sustainably in space, and even inspire cleaner, more efficient ways of producing materials here on Earth,” explains PhD candidate Francisco J. Guerrero-Gonzalez.

Paving the way for turning Moon dust into useful materials

Over a century ago, industries began using molten salt electrolysis to extract aluminium from raw materials – still at the heart of modern terrestrial aluminium production. Researchers are now adapting these technologies for space, investigating how they could extract oxygen and metals in the harsh lunar environment. Adaptations like this are helping pave the way toward turning Moon dust into useful materials, proof that technologies used on Earth can be revamped for space exploration.

It is no simple task – the expensive need to bring supplies from Earth remains and must be addressed.

“To make ISRU truly sustainable, we must minimise what we bring with us to the Moon. One example is developing inert anode materials, special materials that can withstand high temperatures and produce oxygen without being consumed during molten salt electrolysis.”

The majority of known materials cannot stand up to temperatures exceeding 1000°C without degrading, especially considering the highly reactive environment of molten salt electrolysis. Developing materials fit for this challenge still has to happen. The challenge is not new, in fact, aluminium producers, have been trying to solve this issue for decades as part of efforts to reduce carbon emissions on Earth.

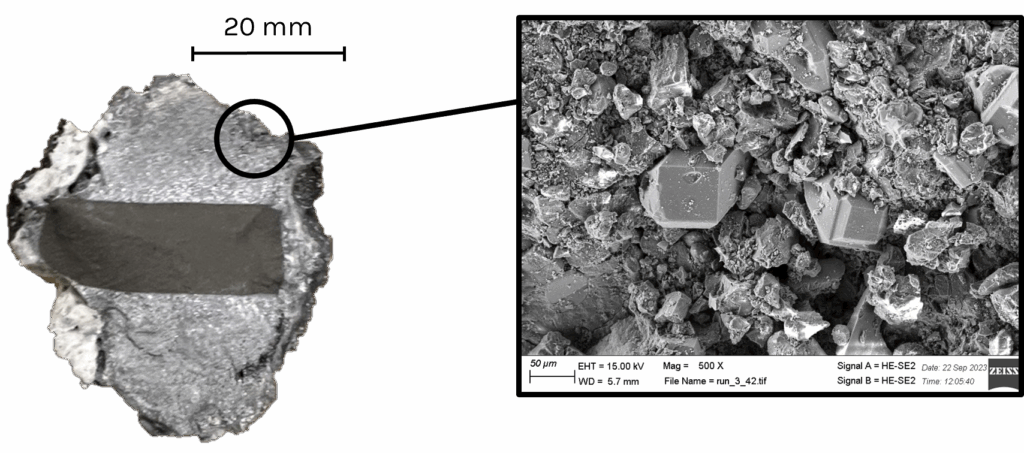

“My research looks at how we can lower the temperature needed for extracting oxygen and metals from lunar soil via molten salt electrolysis. This would broaden the range of materials that could be used in the system, making it easier to find suitable inert candidates. It would also reduce the energy consumption of the process, which is critical on the Moon, where power is limited. To achieve this, we are testing different types of electrolytes – these are salts that melt at lower temperatures and allow electricity to flow through them. They play a key role in enabling the electrolysis process. ”Francisco J. Guerrero-Gonzalez PhD candidate & research fellow working on collaboration between Luxembourg-based company Maana Electric and the Technical University of Munich

Francisco J. Guerrero-Gonzalez is a PhD supported by the FNR’s Industrial Fellowship programme. His project is a collaboration between Luxembourg-based company Maana Electric (supervisor Dr. Mateusz Donten) and Technical University of Munich (supervisor Prof. Philipp Reiss).

MORE ABOUT FRANCISCO J. GUERRERO-GONZALEZ

Describing his research in one sentence

“I am working on turning Moon dust into oxygen and metals using a more energy-efficient process that could help us live and work on the Moon without relying on constant supplies from Earth.”

On his research, peer to peer

“The electrochemical reduction of lunar regolith in molten salts offers a promising route for oxygen and metal extraction on the Moon. My research focuses on identifying and testing low-temperature salt electrolytes that can reduce all major metal cations in the regolith without causing bath poisoning. Lower operating temperatures reduce energy demands and thermal stress on components, improving system longevity. Experimental work includes electrochemical characterization and electrolysis of lunar regolith simulants to evaluate performance and process efficiency.”

Thoughts on working with industry

“In my experience, industry offers a more goal-oriented environment, where milestones and deliverables are reached more quickly. However, this often leaves less room for exploring fundamental research questions in depth. I’ve also found that industry brings together a broader range of professional expertise, which can really benefit a project from multiple angles. Academia, on the other hand, tends to offer deeper, more focused knowledge in specific topics. This can be crucial when tackling technical challenges or overcoming roadblocks in practical research.”

How research benefits from collaborating with industry and vice versa

“Both environments have unique strengths, and working together allows for a more impactful approach to research. When the objectives of both sides are aligned, collaborations between industry and public research can be highly efficient and effective. For industry, especially small and medium-sized enterprises, these partnerships offer access to fundamental knowledge, specialized expertise, and facilities that may not be available in-house, including advanced analytical tools and state-of-the-art laboratories. Academia, in turn, benefits from the goal-oriented mindset of industry, often allowing to translate their research into practical and real-world applications.”

How his academia-industry collaboration looks in practice

“My project, ESPLORE, is a collaboration between TU Munich (Germany) and Maana Electric SA (Luxembourg). In practice, I spend most of my time at Maana’s headquarters in Luxembourg, with occasional short stays in Munich depending on project or training needs. Maana is a small and dynamic company of around 30 people, combining researchers and engineers from diverse backgrounds in applied research. I work closely with my mentor at the company, Dr. Mateusz Donten, who guides me on both scientific and industrial aspects. I also stay connected with my research group at TUM, where I previously worked. They continue to support me and offer opportunities to stay involved with the younger generation, for example by giving guest lectures or supervising student theses related to my work.”

What draws him to research

“I’m drawn to research that isn’t just about curiosity but about solving real-world challenges. Working on technologies that could support human life on the Moon gives it a clear purpose. Contributing, even in a small way, to that goal helps me stay motivated, even when I hit the inevitable setbacks that come with research.”

Why he chose Luxembourg for his project

“The field of ISRU and space exploration is still quite niche in Europe, but Luxembourg has made significant investments to support it, building a strong ecosystem of research institutions and commercial ventures working on it. As I was finishing university, I knew I wanted to stay in Europe and continue developing my career in this field. I also felt that transitioning into industry was the right next step, but I didn’t want to lose touch with academia or stop growing as a researcher. Luxembourg, through the FNR Industrial Fellowship scheme, offered the perfect combination of both worlds. It was a great match for my goals.”

Related Funding Instruments

Related highlights

Spotlight on Young Researchers: Smarter choices for complex systems

Complex systems are part of our everyday lives: smart cars, satellites, medical devices – but if they fail it can…

Read more

Spotlight on Young Researchers: Modelling Forest survival in a changing climate

Forests are dynamic ecosystems – they are used to change but it takes time to adapt. Climate change means drastic…

Read more

Spotlight on Young Researchers: Ensuring sustainable water use for Luxembourg

In Luxembourg, nearly one tenth of water consumption happens in agriculture. Changing rainfall patterns and rising irrigation needs during summer…

Read more

Spotlight on Young Researchers – Revisited: From researcher to project manager

When Xianqing Mao was featured in Spotlight on Young Researchers in 2017, she had completed her medical degree and was…

Read more

Spotlight on Young Researchers: Giving robots a more human touch

The use of robots is rising, both in industry and in homes. This is made possible by scientists leveraging artificial…

Read more

Spotlight on Young Researchers: Cancer in older people & the need for a tailored approach

Cancer in adults aged 65+ is increasing, raising pressure on healthcare systems worldwide, creating economic and social burdens for families…

Read more