BACK TO RESEARCH WITH IMPACT: FNR HIGHLIGHTS

The construction sector consumes over half of the world’s resources, contributes 11% to global CO2 emissions, and produces nearly 50% of all waste. Global initiatives like the European Green Deal and the United Nations’ Sustainable Development Goals are pushing for a climate-neutral economy by 2050, underscoring the urgent need for sustainable construction practices. Researchers and industry are working together to make construction methods more sustainable.

The construction sector plays a substantial role in environmental degradation, it is responsible for significant resources depletion, greenhouse gases emissions, and waste generation.

Research in the area of sustainable construction has made some progress, for example leading to innovations such as steel-timber composite (STC) beams. These beams offer a sustainable alternative to conventional carbon-intensive flooring systems like steel-concrete composite (SCC) floors. Steel-timber composite solutions leverage engineered timber and prefabrication techniques. The aim is not just to reduce emissions, but also to streamline construction processes for better efficiency and less waste.

Main challenge: Conventional construction practices incompatible with sustainable approaches

“The main challenge in transitioning the construction sector toward a circular economy is the incompatibility of conventional construction practices with the principles of disassembly and reuse of structural elements, which is essential for achieving sustainability goals,” explains Alfredo Romero Guzman, Civil Engineer and Doctoral Researcher working with the ArcelorMittal Chair of Steel Construction at the University of Luxembourg.

“A key obstacle is the limitations of current shear connections in steel-timber composite structures, which can damage components upon disassembly, hindering reuse and compromising structural integrity.”

A demountable and reusable steel-timber composite flooring system

Alfredo’s research addresses the pressing need for sustainability in construction by developing a demountable and reusable steel-timber composite flooring system.

“Central to this innovation are the robust shear connections we’ve designed, which enable easy assembly and disassembly without compromising structural integrity. These connections are a key breakthrough, facilitating the reuse of components and significantly reducing the environmental impact of construction.”

“My tests have demonstrated that the novel connectors possess the required load-bearing and deformation capacities for effective use in real-world applications. Full-scale beam tests have confirmed activation of composite action and the potential of the developed steel-timber composite flooring system for reuse, showcasing superior performance and sustainability.”

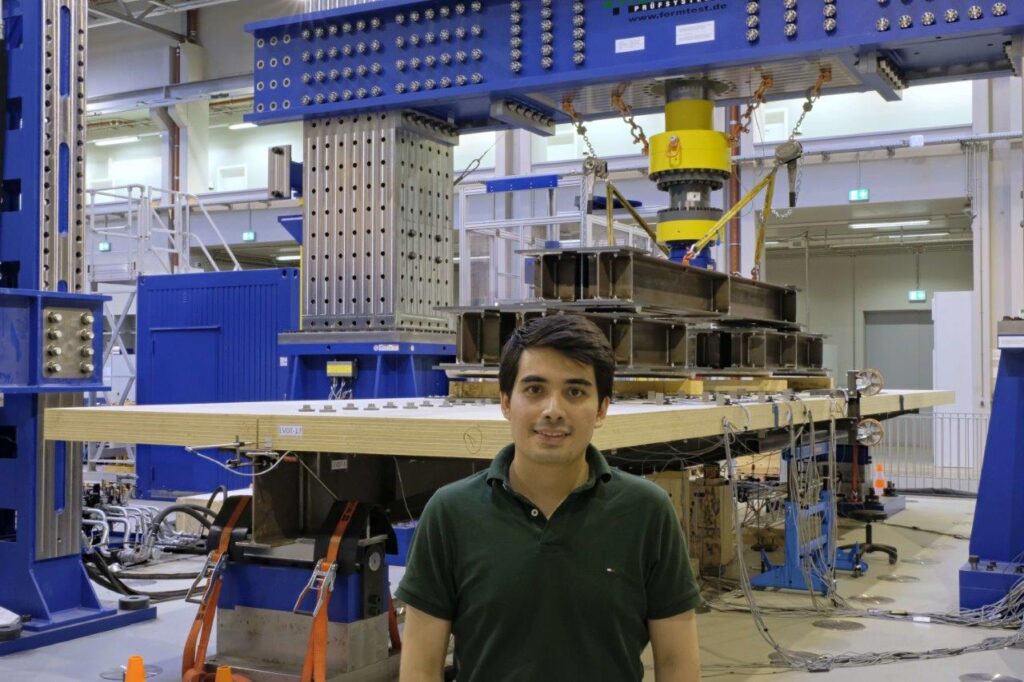

Specimen of beam test and Alfredo Romero

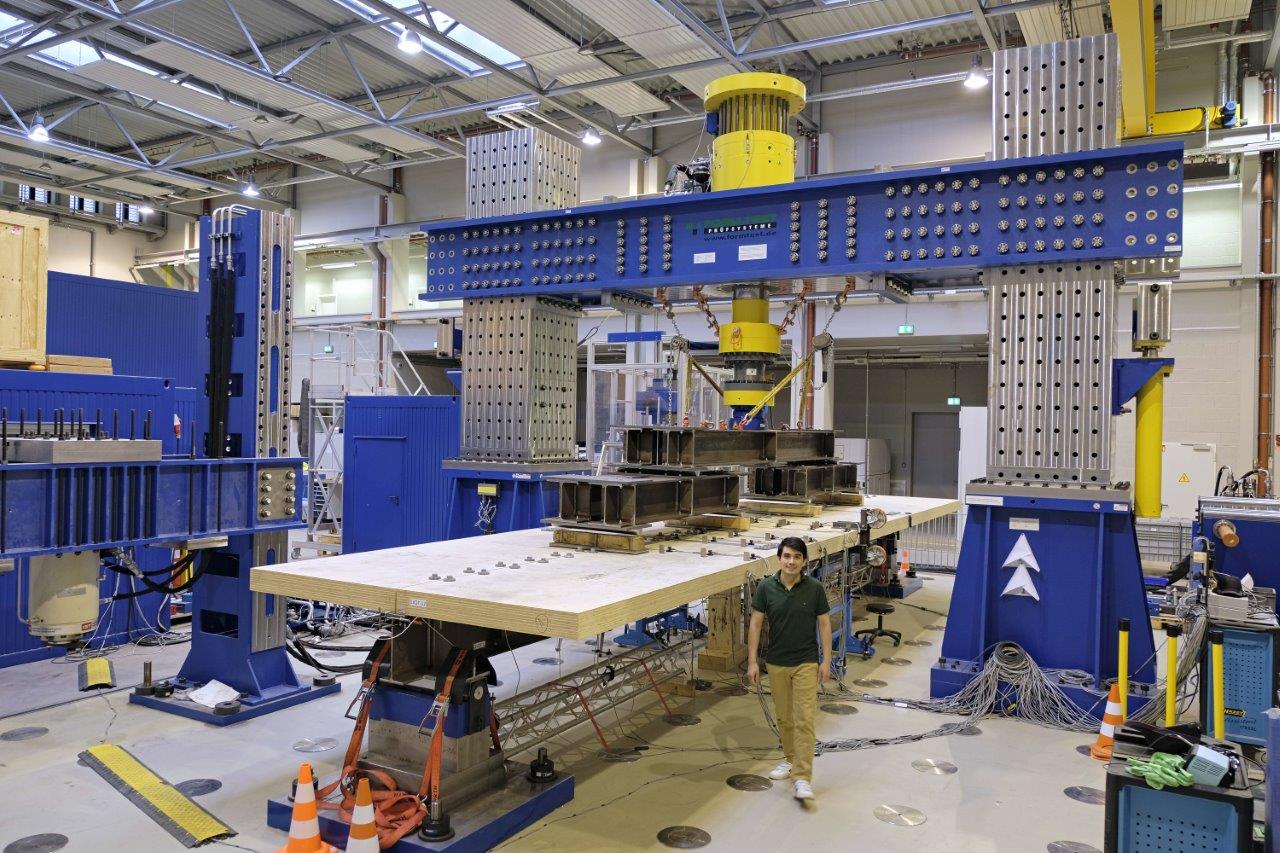

STC beam specimen with a span of 10 meters

STC beam during test

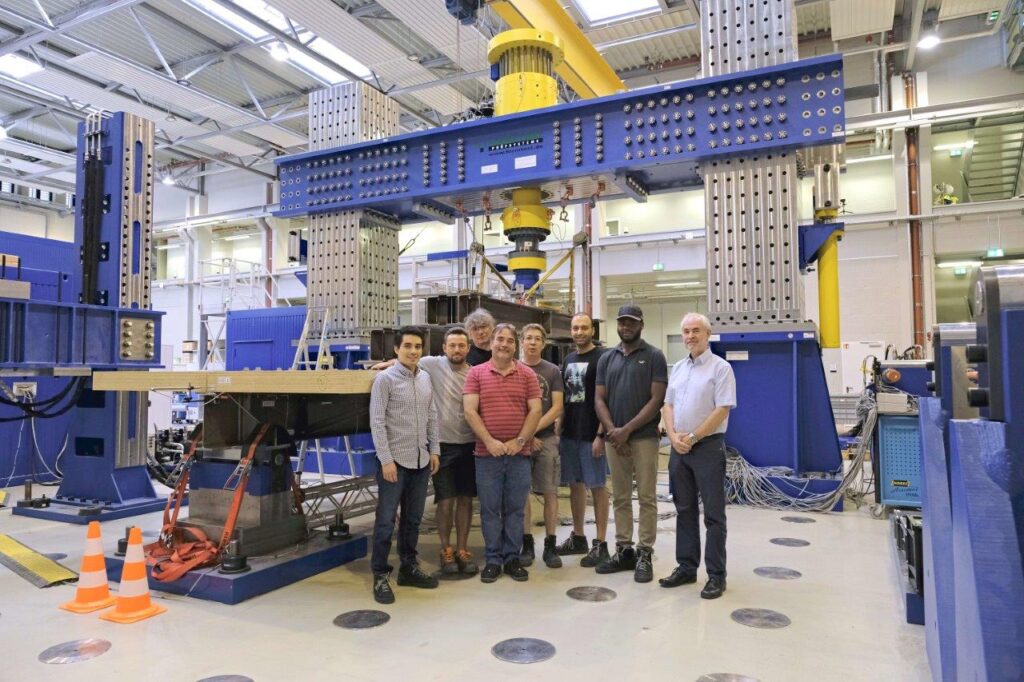

Team involved in beam tests (Alfredo Romero, Cyrille Inglebert, Ed Weyer, Gilbert Klein, Marc Seil, Mehdi Saeidi, Gabriel Ibosiola, Professor Christoph Odenbreit)

Alfredo Romero Guzman, Civil Engineer and Doctoral Researcher working with the ArcelorMittal Chair of Steel Construction at the University of Luxembourg, supervised by Prof Dr.-Ing Christoph Odenbreit, who won an FNR Award for Outstanding Mentor in 2022. His research project is supported by an FNR Industrial Fellowship.

More about Alfredo Romero Guzman

Describing his research in one sentence

“Revolutionising construction through the development of a sustainable, demountable, and reusable steel-timber composite flooring system to foster a circular economy.”

On his research, peer to peer

“The push-out tests indicated the connectors’ exceptional deformation capacity, with load-bearing capacities at a 6 mm slip ranging between 95 and 120 kN. Full-scale bending tests further demonstrated their structural integrity and reusability potential, with slip values less than 1 mm in serviceability conditions, and less than 7 mm even under maximum load conditions, affirming their role in advancing sustainable construction technologies.”

What he loves about science

“Exploring the unknown and tackling the world’s pressing challenges in the construction sector through research motivates me. The process of discovery, innovation, and the prospect of making a tangible difference in the world fuels my passion for this work.”

Where he sees himself in 5 years

“In five years, I aspire to be a leading voice in sustainable construction, contributing to global efforts towards achieving carbon neutrality and a circular economy in the construction industry, potentially leading a research team or projects dedicated to these goals.”

A mentor with an impact

“Throughout my journey, my supervisor Professor Odenbreit has provided guidance, support, and insight that have significantly shaped my research direction and approach to structural engineering and sustainable construction.”

Why he chose Luxembourg for research

“Luxembourg’s proactive approach on sustainability and innovation drew me to conduct my research here. The country’s support for groundbreaking research and its commitment to environmental goals provide an ideal setting for my work on sustainable steel-timber composite structures.”

Related highlights

Spotlight on Young Researchers: Towards fair health for all

Access to essential health services is considered normal in high-income countries, while they are out of reach for many in…

Read more

Spotlight on Young Researchers: Improving protein folding prediction with statistics

Proteins are the building blocks of life: they play an important role in metabolism, immune defence and DNA replication. Their…

Read more

Spotlight on Young Researchers: Building AI tools to help fight disease

AI developments have led to improvements in disease research by enabling new approaches in the study of genes, molecules and…

Read more

Spotlight on Young Researchers – Revisited: From Luxembourg, to Cambridge, France, and an ERC grant

“Would matter be perfect, it would be boring” says Guillaume Nataf, who has an oozing passion for physics and teaching…

Read more

Spotlight on Young Researchers: Advancing ecosystem monitoring with remote sensing and innovative models

The health of terrestrial ecosystems is intricately linked to the sustainability and stability of society: forests, grasslands, and cropland, play…

Read more

Spotlight on Young Researchers: Unravelling the role of calcium signalling to overcome melanoma drug resistance

Cutaneous melanoma is the most serious type of skin cancer and the sixth most frequent cancer in Europe. Despite progress…

Read more